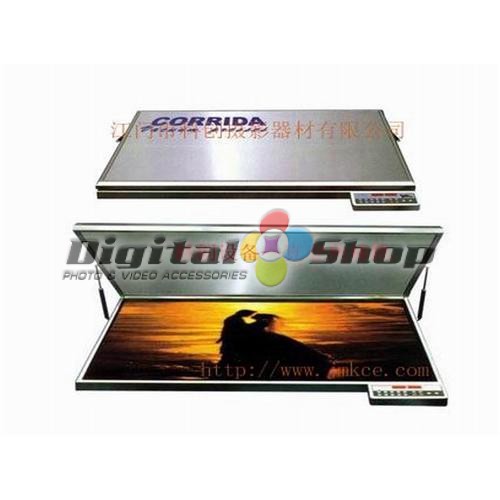

This is the ideal machine for applying a protective film or a tissue on top of a picture or a painting. The press is hermetically closed after inserting the material to be mounted, the board and a sheet of special heat sensitive adhesive. The press is sealed and the air is extracted with a vacuum pump, forcing the rubber against the plate. The temperature reaches about 90° so the adhesive can soften and bond to the board. Same operations are made for the hot laminating that consists in applying a PVC film on top of a picture for protecting from dust, dirt, etc.

The protective film is available with gloss, matt and other finishings. This process is often used for giving a special look to photos and photo-enlargings.

With the HOT VACUUM PRESSEN is possible also to obtain the Canvas Effect: this method gives an oil painting look to prints or photos because the canvas can be seen underneath.

Microprocessor technique: micro-computer accurate the pressures of mounting,

temperature and time. This advanced the working efficiency and makes sure that the product has the best outcome.

Imported parts speed up the vacuum hence thermo-pressing and mounting can be done in minutes.

Enclosed multi-infrared rays distribute the temperature evenly.

Computer automatically examines and control time, temperature and vacuum.

Touch-screen key boards are easier to use

Automatic diagnosis ensures the security of the machine and the products.

It is completely sealed which avoids gas leaking and damage to the rubber.

There is a temperature balance device in the computer that saves energy used by the machine.

Exclusive design of separating heat plate and gasket board. Creative adjustment available for seal functions.

Mounting thickness : 0,1 - 30 mm

Mounting temperature : 50° C - 120° C

Mounting time : 0 - 30 min

Vacuum pressure : 0.07 - 0.09 mpa

Mounting size : 1100mm X 1540mm

Voltage : 220V

Power : 2.5 KW

External size : 1180 X 1620 X 150mm

Weight : 80kg